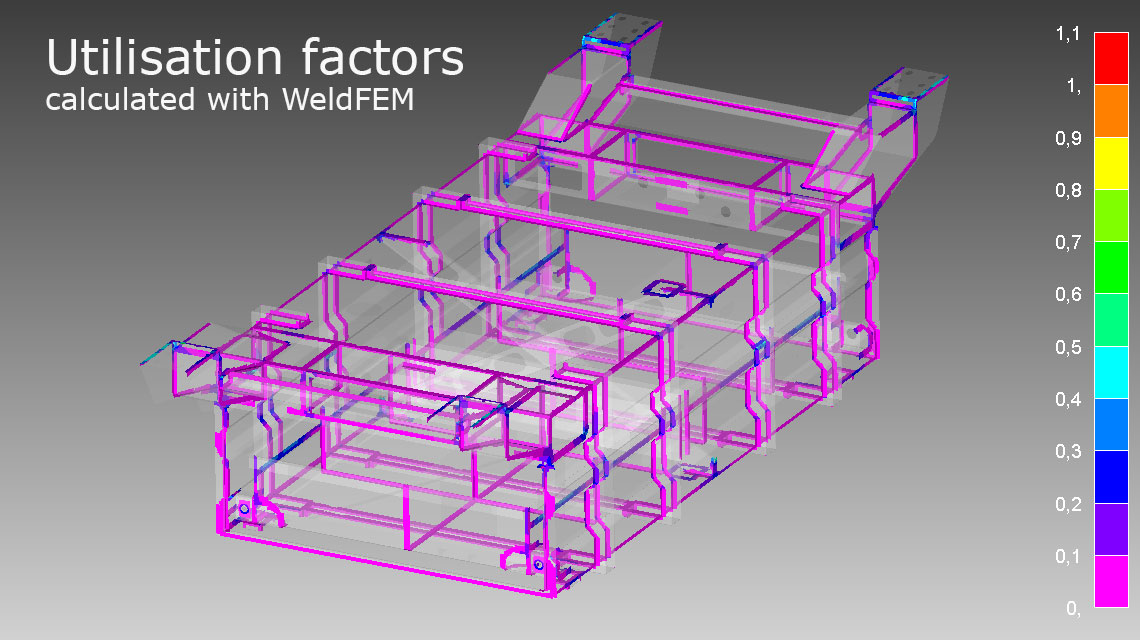

Weld assessment

WeldFEM provides static and fatigue strength assessments for welds.

Guidelines and standards for steel construction, rail vehicle construction and crane construction including load lifting attachments are currently supported.

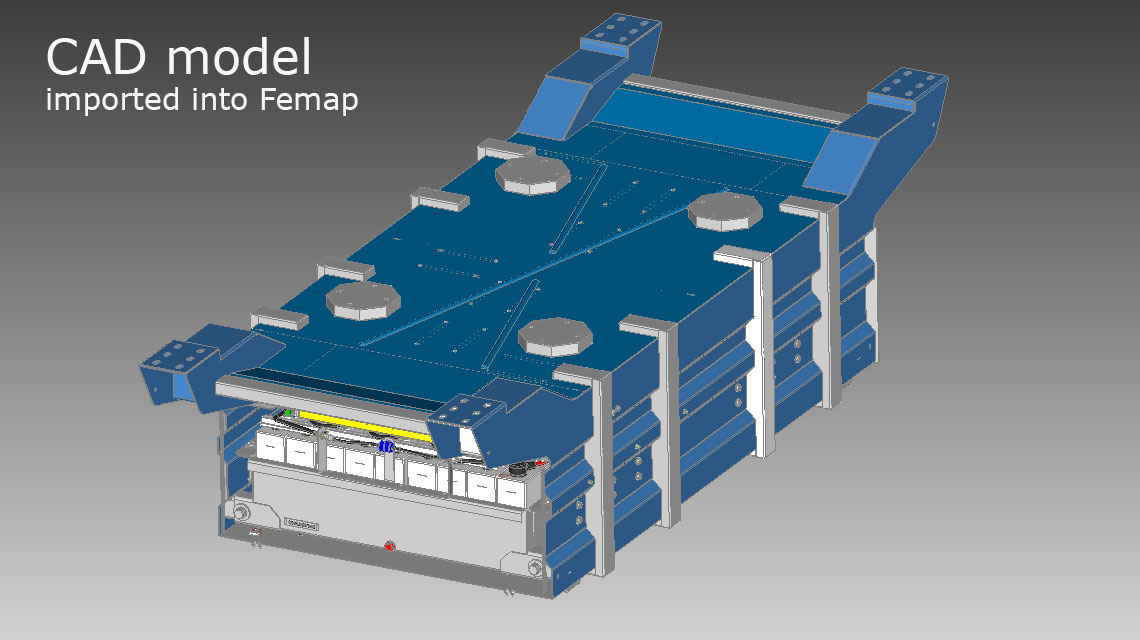

FEA Software – Connection

WeldFEM is executed in parallel with the FEA software. Both programs communicate continuously.

Currently, Simcenter Femap from Siemens PLM Software and MSC Apex from Hexagon are supported.

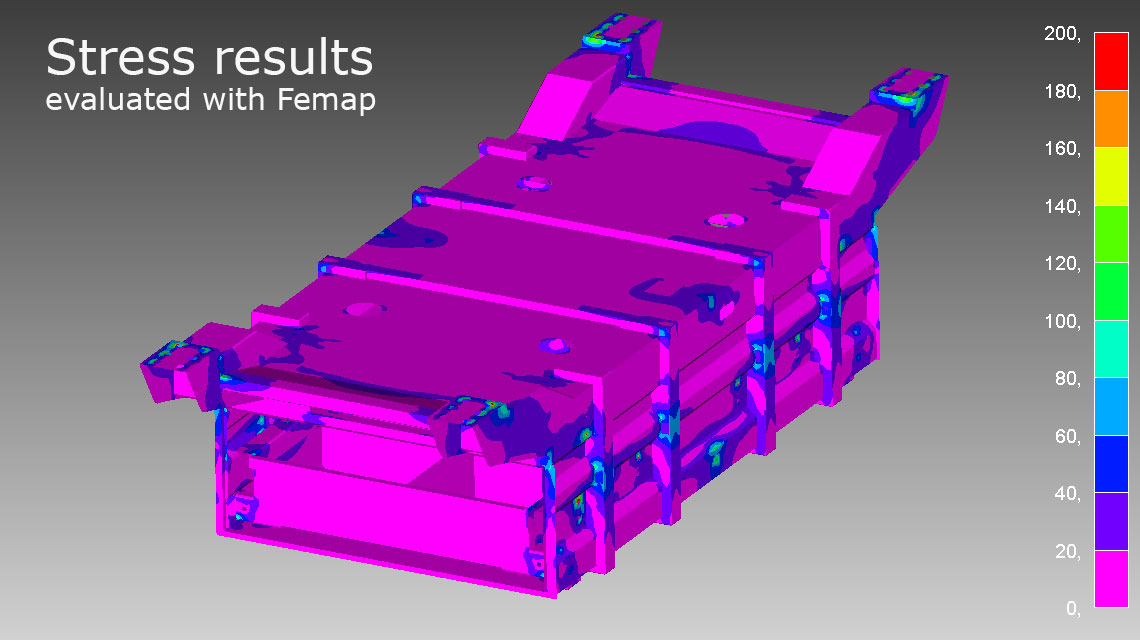

The FEA software provides the model and the stresses, WeldFEM results are displayed and evaluated in the FEA software.

Support

WeldFEM was developed for up-to-date assessments and proves its performance in daily practice.

Support includes training and hotline. Assessments can be provided as a service.

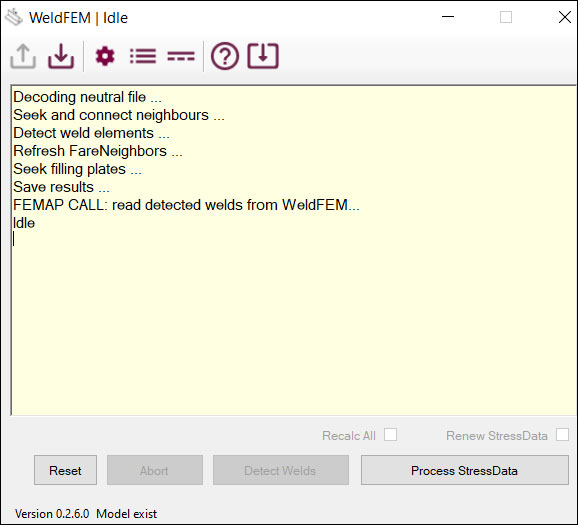

WeldFEM Main Window

The control center! All steps required to perform the weld assessment are controlled here.

The required calculation options for the verification are set. After the weld detection, the utilisation factors are calculated for a preliminary design with conservative parameters. Each weld is available for design layout in the weld editor for a successful assessment. The results of design changes are immediately monitored in the FEA software.

The info area logs the current design progress. The design status can be saved and loaded at any time.

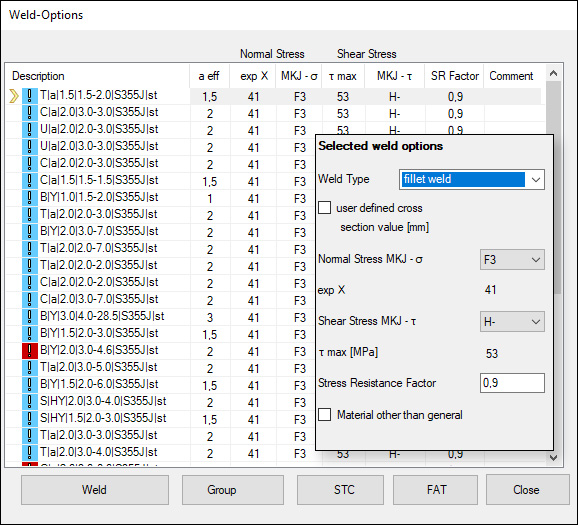

Weld seam editor

All welds are distinctly listed in the weld editor. All parameters of a weld seam (such as weld type and thickness) are edited here in order to adapt them to the assessment requirements. The editor monitors the plausibility of user entries. An optimization feature is available for minimizing the weld seam thickness. Symbols and color coding indicate the design status and the assessment success.

Each weld seam with its utilisation factors can be evaluated at any time in the FEA software.

After completion of the design, the utilisation factors are prepared and available for the assessment report.

Standards & Guidelines

Currently supported guidelines and standards:

EN 1993 (Eurocode 3), DVS 1612, DVS 1608, EN 13001

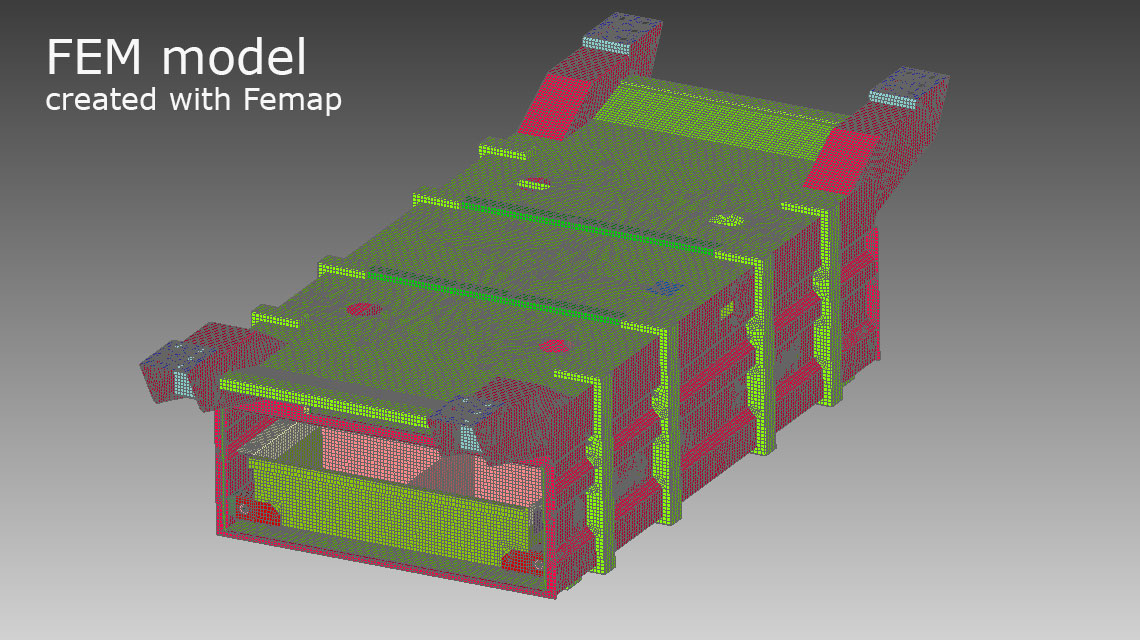

Import of FEM data

Import of the active FEM model as well as the FEM stress results from the FEA software. Simple denoting of profiles in the FEM model for weld seam recognition.

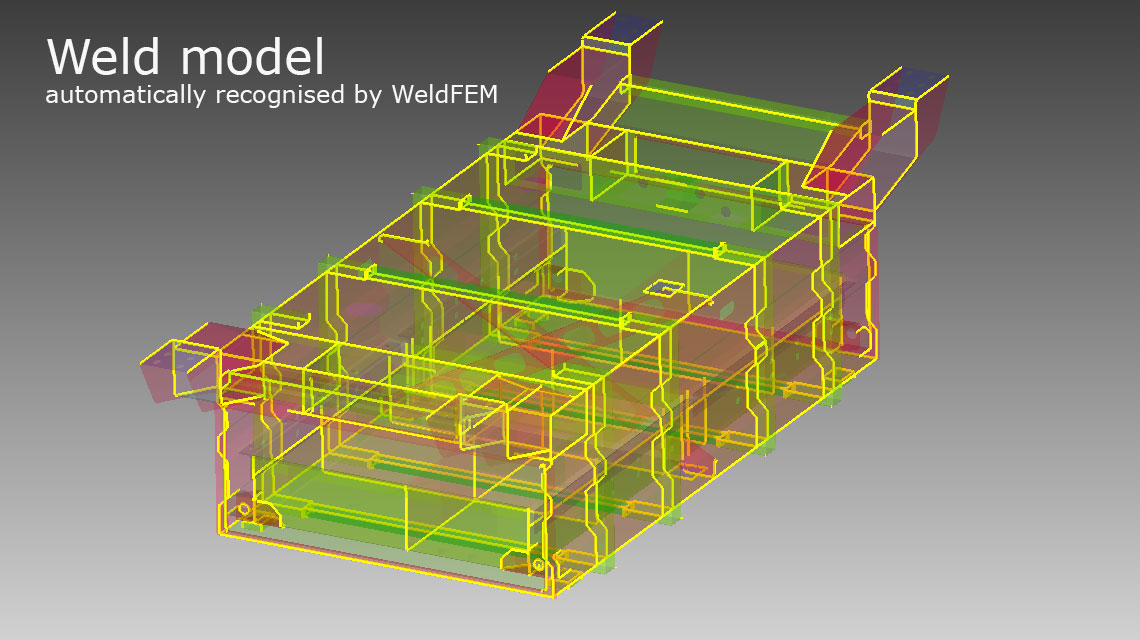

Weld detection

Automatic detection of welds and joint-types in FEM shell models, no need for cumbersome preparation in the FEM model.

Weld seam editor

Editing of weld shape, section dimension and verification parameters, splitting and merging of welds, optimization of individual weld cross-sections.

Result visualisation

Display and evaluation of utilisation factors calculated by WeldFEM in the FEA software..

Save & Load

Save and load weld configurations consistent with the model in the FEA software.

Online Manual

Take a look into the Online Manual.

WeldFEM – YouTube Channel

Theory & Practice